Products

Contact Information

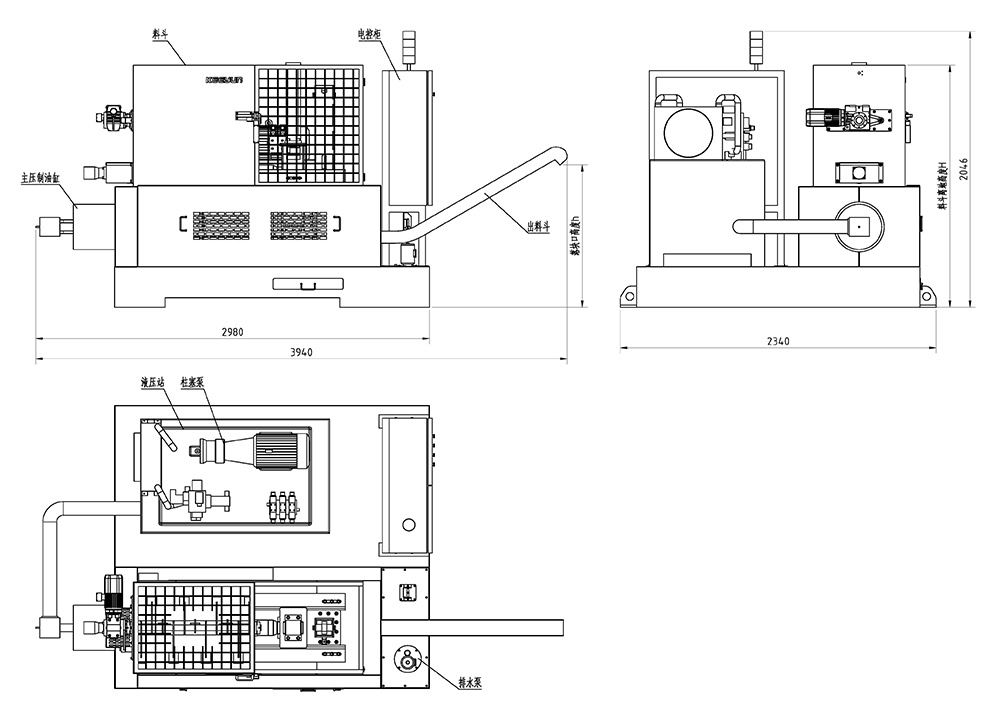

KE2B-3 Reciprocating Extruder

Reciprocating extruder is mainly used for cold extrusion and dehydration of abrasive dust of various materials, so as to reduce capacity of abrasive dust and collect cutting fluid.

The machine comprises hydraulic system, control system, storage and material feeding and extrusion forming. Work flow is that the material in the bucket is fed by inner spiral, materials are pressed into extrusion container through pre-pressing fixture, and main oil cylinder slowly pushes for extrusion and dehydration, material-blocking shutter lifts and pushes out the dehydrated abrasive dust. Hydraulic system adopts axial plunger pump and cartridge valve, which is able to adjust extruding speed and pressure in accordance with types of abrasive dust. Design of draining channel ensures that fluid is able to drain smoothly. Full automatic control enables automatic operations when materials are available, and stand-by where materials are absent, so that energy consumption is minimized. Storage and materials feeding system ensures even feeding without bridging. Extrusion forming mold adopts abrasion resistance materials.

Reciprocating extruder is divided into three models.

- Commodity name: KE2B-3 Reciprocating Extruder

Technical parameters

|

Model |

Materials bucket capacity/m3 |

Power/KW |

Forming size/mm |

Pressure/T |

Estimated weight/T |

|

KE2B-1 |

0.1 |

7.5 |

ф7O×8O(max.) |

60 |

1.2 |

|

KE2B-2 |

0.2 |

11 |

ф8O×12O(max.) |

100 |

2.7 |

|

KE2B-3 |

0.35 |

18 |

ф1OO×13O(max.) |

200 |

3.5 |

Key words:

Keeyun Machinery |

Machine tool |

Cutting fluid |

Reciprocating Extruder |

Product Consulting

Note: Please leave your phone number and our professionals will contact you as soon as possible!

Related Products