Cutting Fluid Life Cycle

Excellent period of cutting fluid

Excellent period of cutting fluid

Slightly pollution period of cutting fluid

Slightly pollution period of cutting fluid

Moderate pollution period of cutting fluid

Moderate pollution period of cutting fluid

Heavy pollution period of cutting fluid

Heavy pollution period of cutting fluid

Original liquid

Lubrication, cooling, cleaning, anti-corrosion, etc. of machined parts

Existing problems

Manual dosing, time-consuming and laborious, inaccurate dispensing accuracy, etc.

Solution

The use of Italian matching pump, accurate liquid distribution, intelligent electronic control, fixed-point positioning, flexible maneuverability

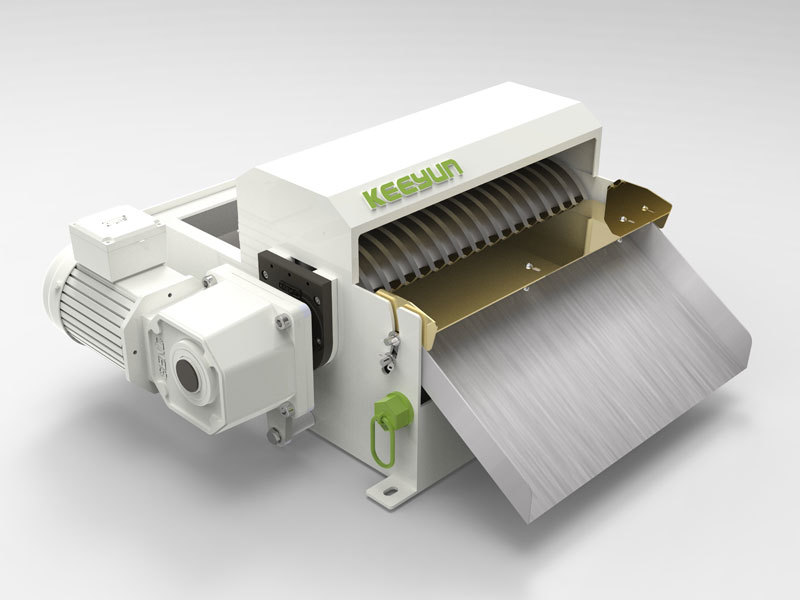

Magnetic-absorbing powder, mud, flocculent and other abrasive debris

The machine tool has no requirements for filtration accuracy

Existing problems

The use of cutting fluid is easy to scratch the workpiece and affect the machining accuracy

Solution

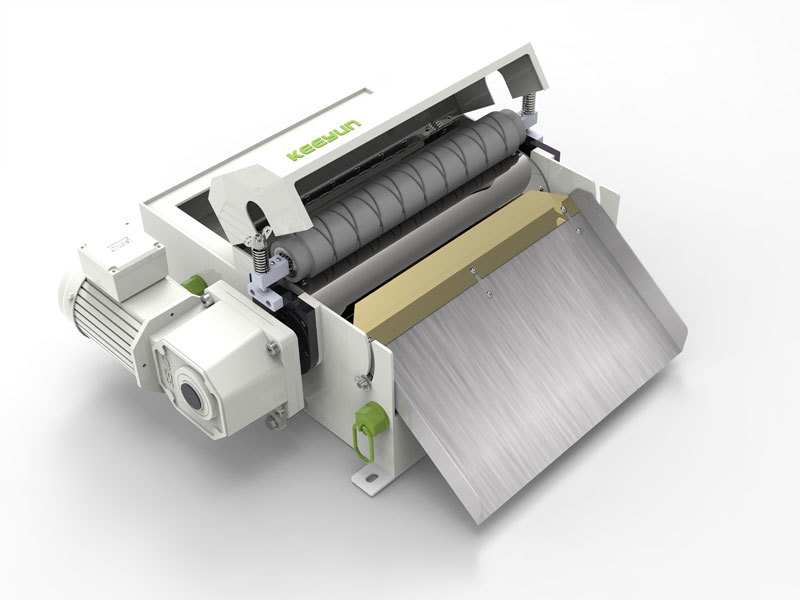

The magnet in the magnetic cylinder is used to absorb the iron shavings and wait until the surface of the magnetic cylinder, the magnetic cylinder rotates to the chip outlet, and the chip scraper scrapes the shavings off the magnetic cylinder.

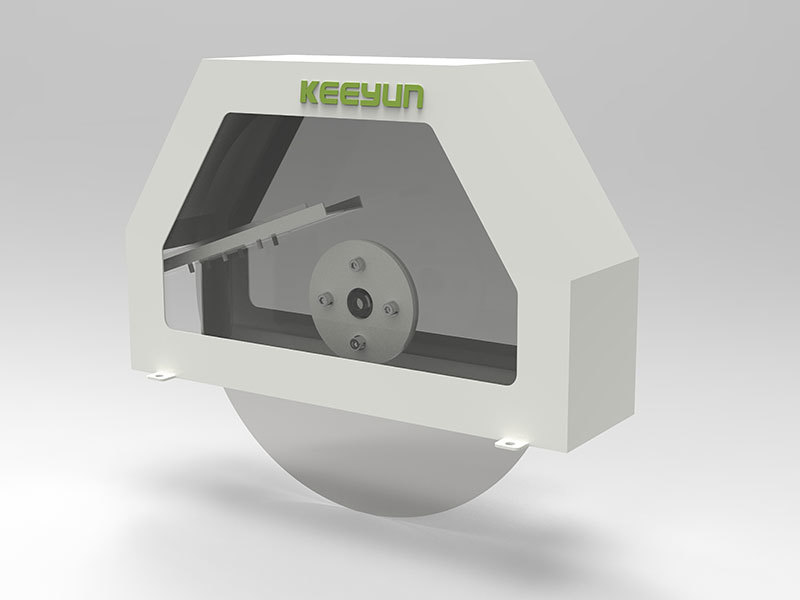

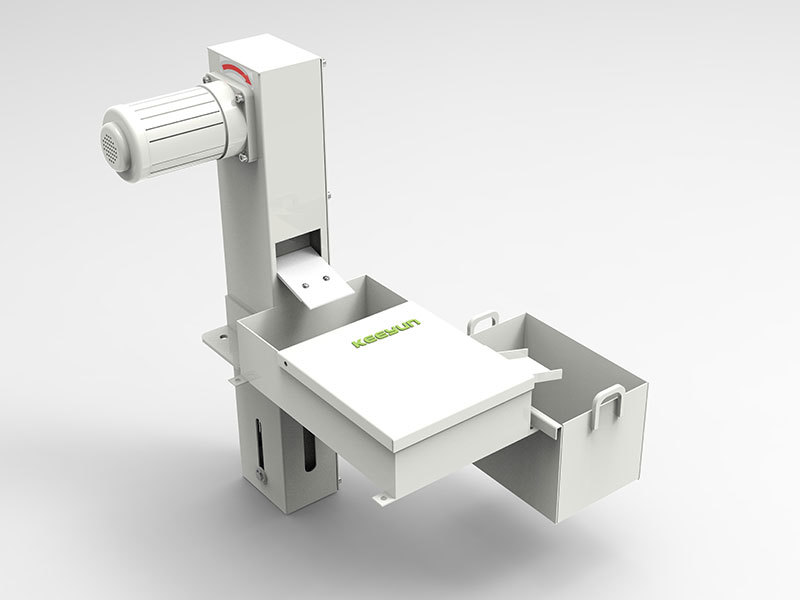

Magnetic-absorbing granular, flaky and needle-like chips

The machine tool has no requirements for filtration accuracy

Existing problems

The use of cutting fluid is easy to scratch the workpiece and affect the machining accuracy

Solution

The magnet in the magnetic cylinder is used to absorb the iron shavings and wait until the surface of the magnetic cylinder, the magnetic cylinder rotates to the chip outlet, and the chip scraper scrapes the shavings off the magnetic cylinder.

Chips that are larger than the specific gravity of the cutting fluid

Existing problems

The use of cutting fluid is easy to scratch the workpiece and affect the machining accuracy

Solution

Using the principle of large specific gravity difference between chips and cutting fluid, the chips are separated from the liquid

Non-magnetic powder, granular, flaky, flocculent, muddy and other debris and impurities

Machine tools have requirements for filtration accuracy

Existing problems

The filtration accuracy is not up to standard, which can easily affect the smoothness of the surface of the workpiece. At the same time, the silt deposited in the liquid tank needs to be cleaned frequently.

Solution

The cutting fluid is used to pass through the filter cloth into the net liquid tank under the action of gravity, and impurities that are greater than the filtration accuracy of the filter cloth are trapped on the filter cloth for filtration.

Magnetic-absorbing powdered, granular, flaky, flocculent, muddy and other debris and impurities

Machine tools have requirements for filtration accuracy

Existing problems

The filtration accuracy is not up to standard, which can easily affect the smoothness of the surface of the workpiece. At the same time, the silt deposited in the liquid tank needs to be cleaned frequently.

Solution

Use the principle of magnetic adsorption and cutting fluid permeable filter cloth under gravity for filtration

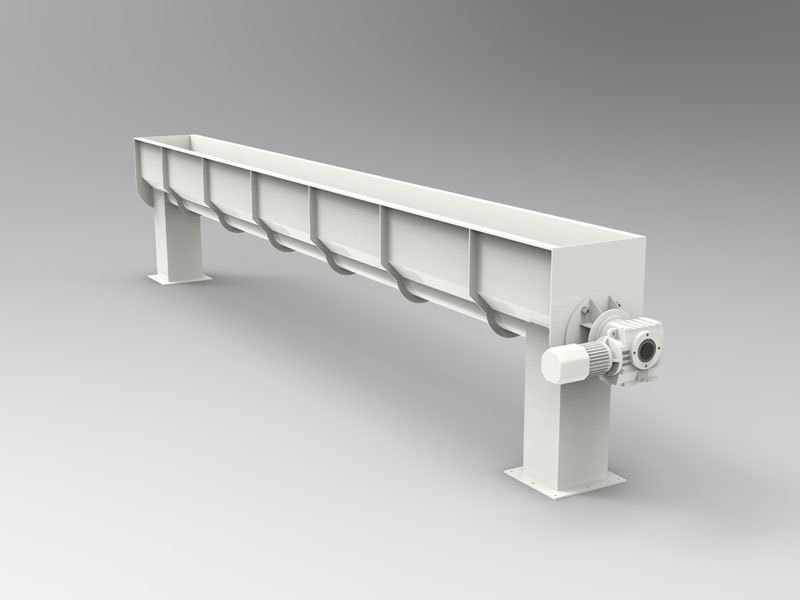

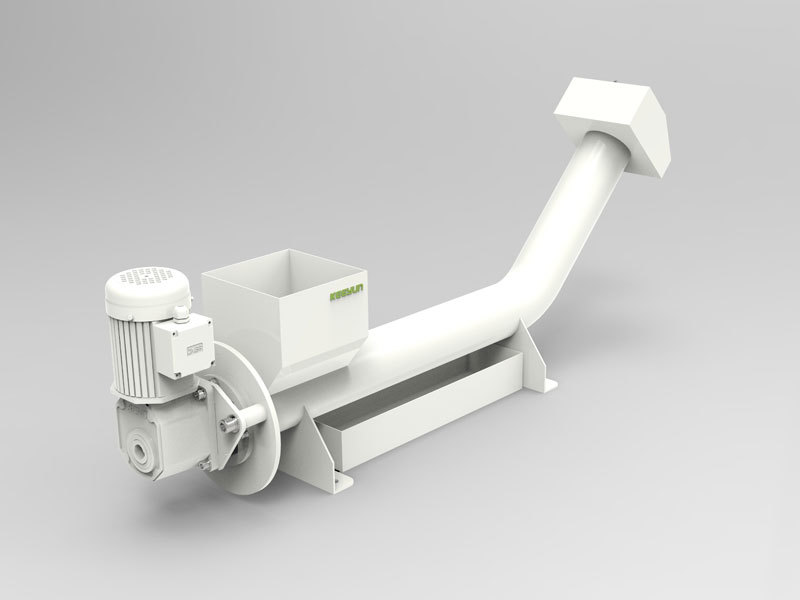

Powdered, small strips, flakes, granular steel, cast iron, copper, aluminum (machine tool dry processing, no cutting fluid), non-metals and a large number of chips and impurities

Existing problems

Due to the large amount of chips, the space is filled with chips in a short time, which affects production and processing.

Solution

Drive the scraper assembly or spirochete to rotate and transport the chips that fall into the bottom of the chip removal machine out of the equipment

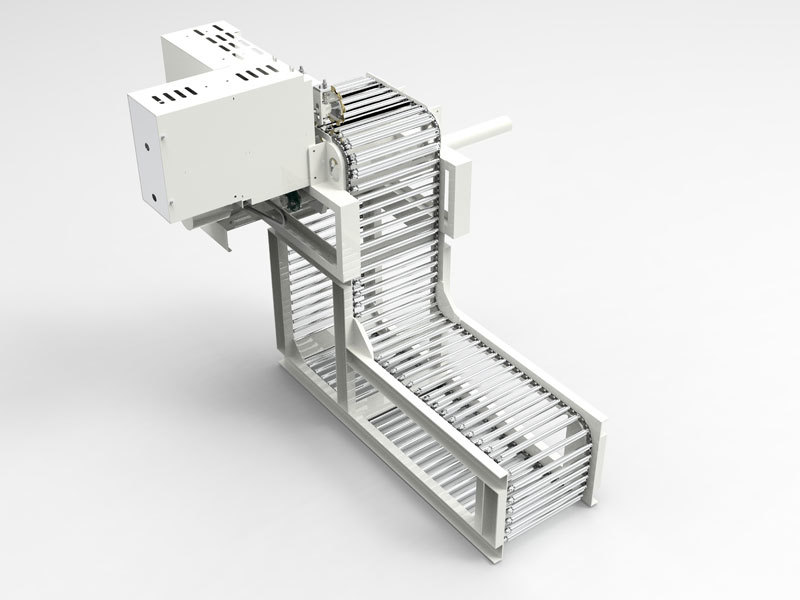

A large number of steel, cast iron, copper, aluminum, non-metallic shavings and impurities in strips, flakes, and clusters

Existing problems

Due to the large amount of chips, the space is filled with chips in a short time, which affects production and processing.

Solution

Drive the rotary movement of the articulated chain plate to transport the chips that fall on the articulated chain plate out of the equipment

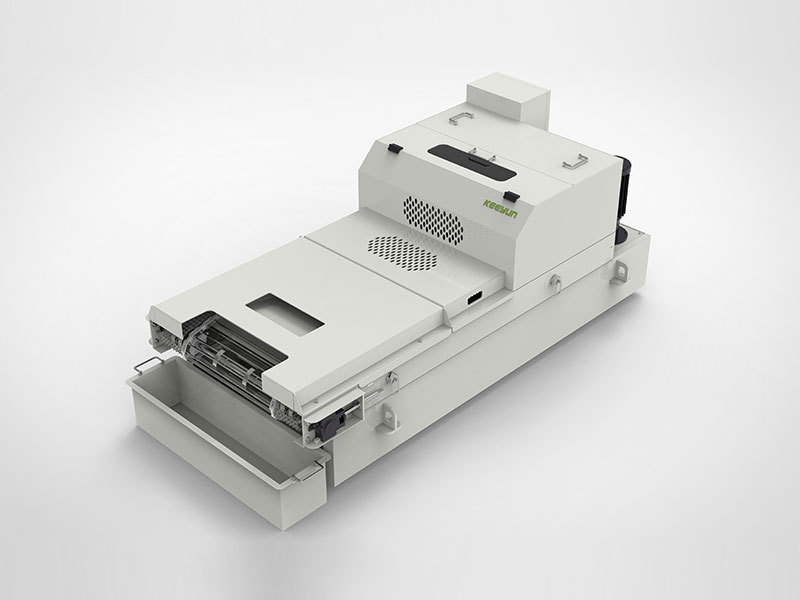

A large amount of finely broken aluminum shavings and impurities

Machine tool wet machining, with cutting fluid

Existing problems

Due to the large amount of chips, the space is filled with chips in a short time, which affects production and processing.

Solution

The cutting fluid enters the rotary cylinder through the filter outside the rotary cylinder, flows into the net liquid tank, and transports the aluminum shavings trapped outside the rotary cylinder out of the equipment.

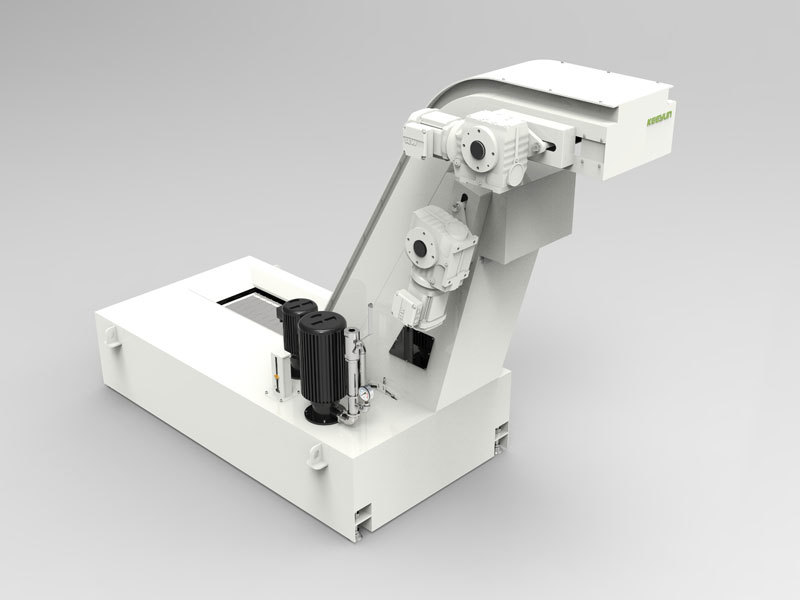

A large number of steel, cast iron, copper, aluminum, non-metallic shavings and impurities in strips, flakes, and clusters produced by heavy-duty processing

Existing problems

Due to the particularly large amount of chips, the space is filled with chips in a short time, which affects production and processing.

Solution

The hydraulic system drives the push block to move back and forth in the equipment to transport the chips that fall into the chip removal machine out of the equipment.

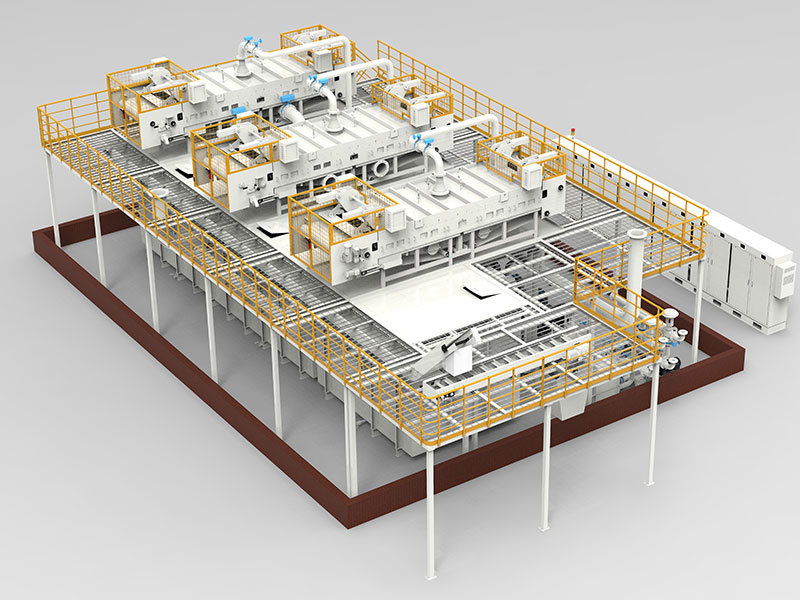

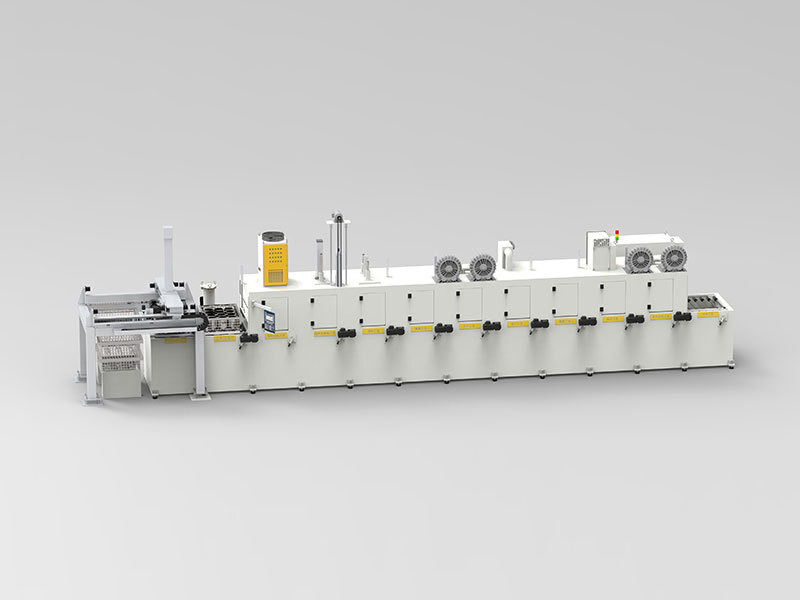

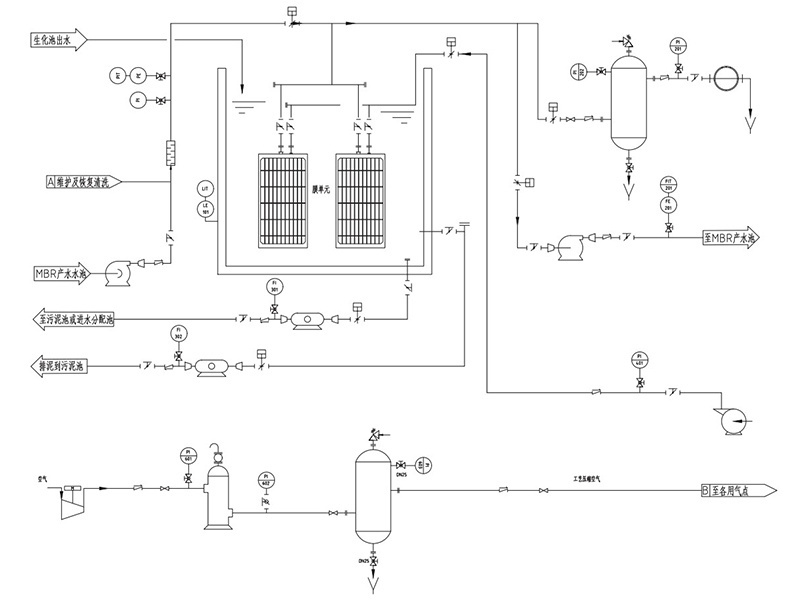

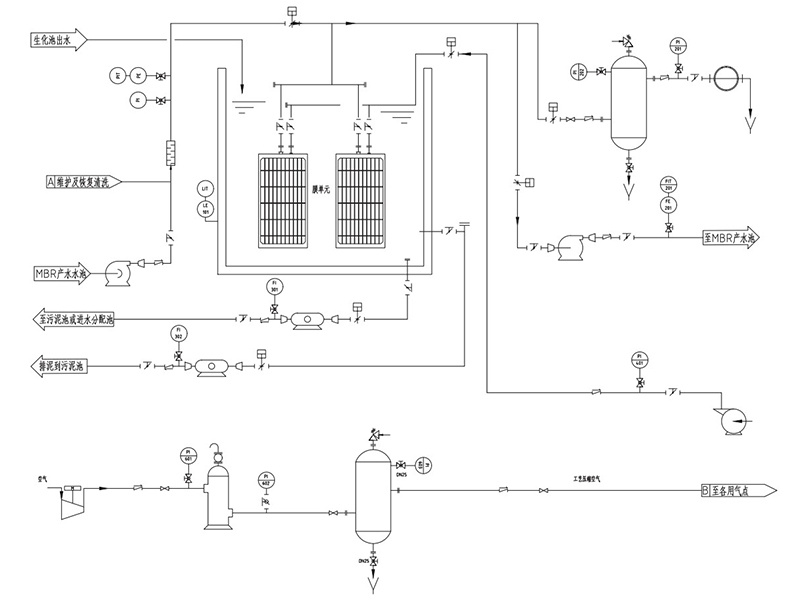

Chips, oil slick, etc. processed by multiple machine tools at the same time

Existing problems

Multiple machine tools are processed at the same time on site, which are dirty, messy, poor, and slow in work efficiency, and need to be fully automated.

Solution

Centralized processing, automatic dispensing, filtration, degreasing, sterilization, remote control, recycling, etc.

Oil mist generated by machine tool processing

Existing problems

It has a certain impact on environmental pollution and the health of the operator

Solution

Through the filter inside the equipment, the larger oil droplets are intercepted and the oil mist is separated.

Steam generated by the cleaning machine cleaning the workpiece

Existing problems

Causing the humidity of the space to increase, causing the electrical system to fail

Solution

The apparent heat exchange core is used to condense the oil mist and water mist into a liquid for treatment.

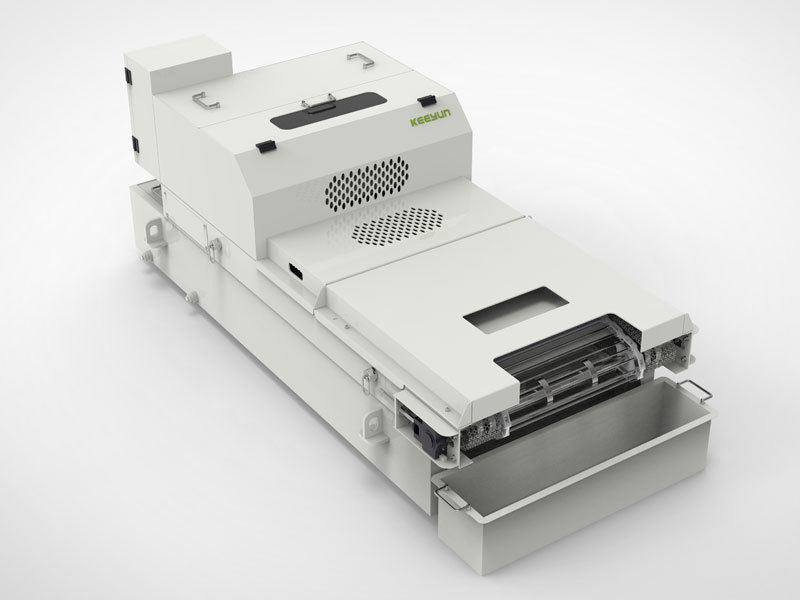

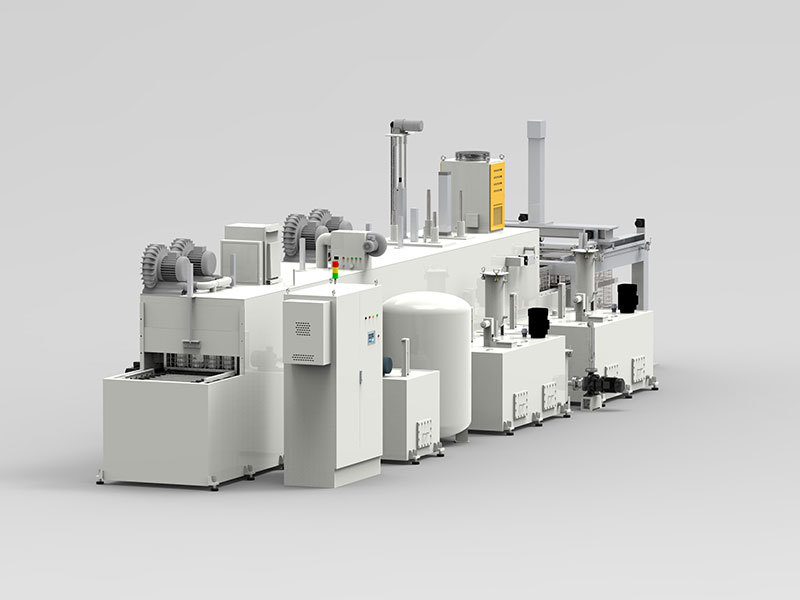

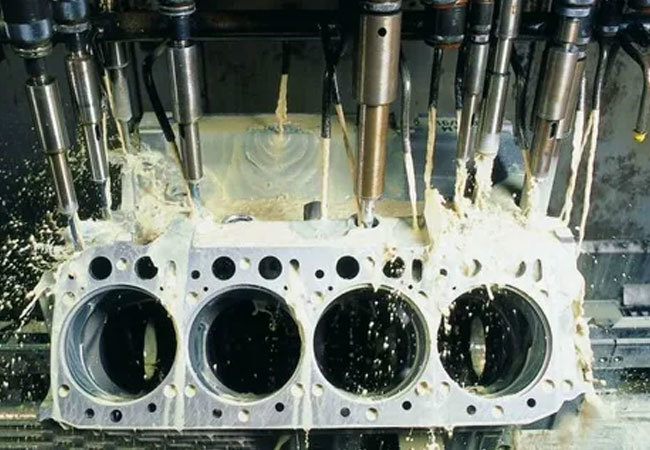

Impurities and oil stains that adhere to the surface of the workpiece, etc.

Existing problems

Affect the processing quality of the next process or the use of the workpiece

Solution

Complete the cleaning of the workpiece through the processes of conveying, cleaning, drying, filtering, and conveying the workpiece

The information is a test element. When using, you can delete the element and place the element you want to put.

Here is the placeholder text

The information is a test element. When using, you can delete the element and place the element you want to put.

YANTAI KEEYUN MACHINERY CO., LTD

Keeyun borrows the meaning of 'Unfounded worries' And 'A gale has risen and is sweeping the clouds' and was named it means maintaining crisis awareness at all times and owning tenacious fighting spirit and bold quality.

Since the company was founded in March 2000, all the staff have overcome the obstacles and accumulated sand to form a pagoda. Currently registered capital is RMB 10 million, and more than RMB 50 million fixed asset. There are two production plants with 15,000㎡of usable production and processing area in Yantai. In 2022, a branch was set up in Suzhou. Suzhou Keeyun can provide convenient services for Customers around the Yangtze River Delta.

Established in 2000

10 million of registered capital

Production and processing area of 15000 ㎡

More than 30 national patents

BLOG

Win-Win Cooperation

Innovation and win-win cooperation

Brand trust choice

Long-term cooperative customers: Doosan Machine Tool, SAIC, China Aviation Industry Corporation, Grundfos Water Pump Co., Ltd., Hebei North China Diesel Engine, Taigang Group and a large number of enterprises, providing them with one-stop cutting fluid application solutions.